Place of Origin: Shenzhen, China

Base Material: FR4/FR1/ FR2/ FR3/ etc

Board Thickness: 0.15mm

Min. Hole Size: 3mil

Min. Line Width: 3 mil

Min. Line Spacing: 3mil

Surface Finishing: HASL leed free,Imm Au,etc...

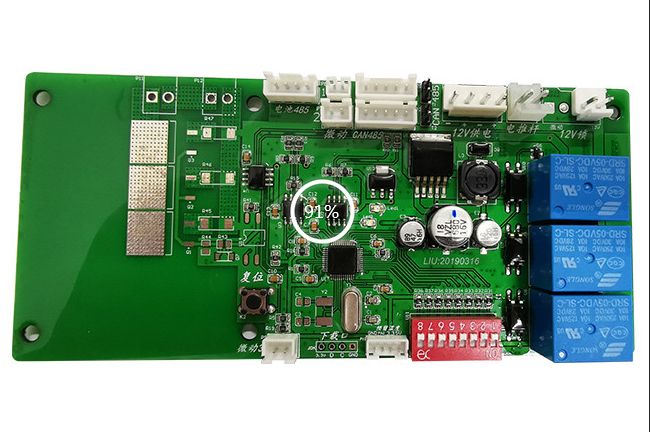

Product name: Multilayer OEM/ODM PCB/PCBA, manufacturing of Printed Circuit Board

Max board size: 700*1200mm

Certificates: ISO/UL/TS16949/RoHS/TS16949

PCB Standard: IPC-A-610 D/IPC-III Standard

PCB assembly FAQ:

What is the main impact on the quality of the pcba processing?

(1) SMT quality affected by human behavior includes: lack of skill, fatigue of work, insufficient personnel allocation, insufficient training, emotional work, non-conformity of vision, etc.

(2) SMT quality affected by machine behavior includes: insufficient air pressure, machine failure, placement accuracy, poor horizontal adjustment, worn parts, unsatisfactory air supply, camera illumination, and incorrect settings.

(3) The SMT quality affected by material behavior is: pin oxidation, pcb deformation, pin deformation, non-conformity of packaging, improper manufacturing process of pcb, design of PCB, foreign matters on the bonding pad, and expiration of solder paste.

(4) The SMT quality affected by the behavior of the process method as follows: solder paste temperature and storage, furnace temperature setting, time to be welded, incorrect printing parameters, process inspection sequence, stencil design, first piece confirmation.

(5) The SMT quality affected by the behavior of the processing link is as follows: workshop environment, ESD anti-static protection, lighting, humidity, cleanliness and noise.

Based on the above information, do you know how to select a qualified PCB manufacturer or PCB assembly factory?

PCB assembly FAQ:

What is the main impact on the quality of the pcba processing?

(1) SMT quality affected by human behavior includes: lack of skill, fatigue of work, insufficient personnel allocation, insufficient training, emotional work, non-conformity of vision, etc.

(2) SMT quality affected by machine behavior includes: insufficient air pressure, machine failure, placement accuracy, poor horizontal adjustment, worn parts, unsatisfactory air supply, camera illumination, and incorrect settings.

(3) The SMT quality affected by material behavior is: pin oxidation, pcb deformation, pin deformation, non-conformity of packaging, improper manufacturing process of pcb, design of PCB, foreign matters on the bonding pad, and expiration of solder paste.

(4) The SMT quality affected by the behavior of the process method as follows: solder paste temperature and storage, furnace temperature setting, time to be welded, incorrect printing parameters, process inspection sequence, stencil design, first piece confirmation.

(5) The SMT quality affected by the behavior of the processing link is as follows: workshop environment, ESD anti-static protection, lighting, humidity, cleanliness and noise.

Based on the above information, do you know how to select a qualified PCB manufacturer or PCB assembly factory?