HDI PCB

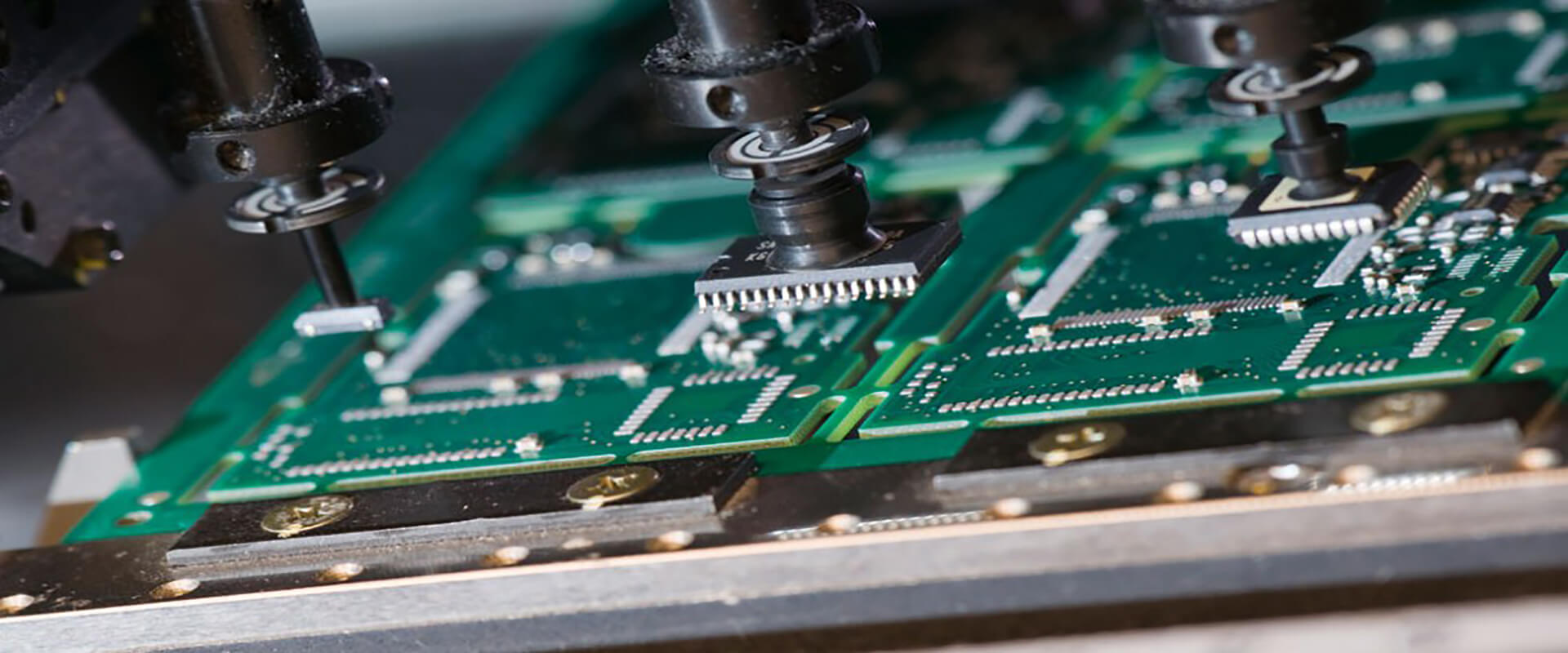

The high-density interconnector (HDI PCB), is one of the fastest-growing technologies in the PCB industry. HDI PCB boards contain blind vias and/or buried vias. Typically contain microvias with a diameter of .006 or less. HDI PCB has a higher circuit density than conventional PCB boards.

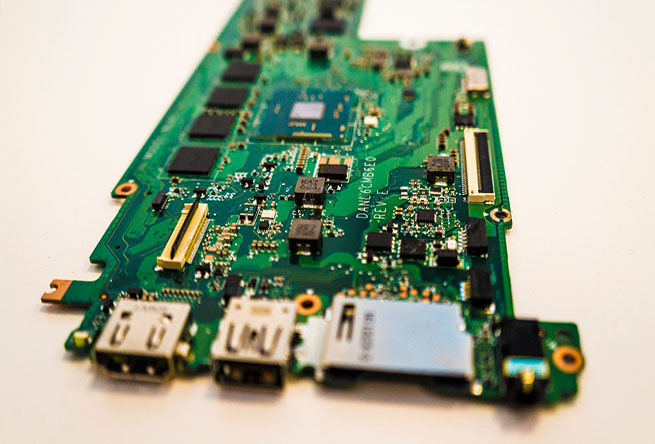

HDI PCB uses a micro-blind buried hole technology for a circuit board with a relatively high density of line distribution. It has an inner layer line and an outer layer line, and then uses a process such as drilling and metallization in the hole to connect the inside of each layer. HDI board is a compact product designed for small-size products.

HDI PCB has made great progress in the medical industry. Treatment equipment often requires a small package with a high transfer rate, which is only available with HDI PCB. For example, implants need to be small to fit the human body, while requiring that any electronic device involved in the implant must absolutely effectively allow high-speed signals to be transmitted well. Here, the HDI board shows its great value. HDI PCBs can also be used in other medical devices such as emergency room monitors, CT scans, and so on.

Electronic products continue to develop toward high density and high precision. The so-called "high", in addition to improving machine performance, also reduces the size of the machine. High-density integration (HDI) technology enables the end-product design to be more compact while meeting higher standards of electronic performance and efficiency. Currently, popular electronic products, such as mobile phones, digital cameras, notebook computers, automotive electronics, etc., are mostly using HDI boards. With the upgrading of electronic products and the needs of the market, the development of the HDI PCB will be very rapid.

The benefits of HDI PCB

1. Reduce PCB cost: when the density of the PCB increases beyond the eight-layer board, the cost of using the HDI board is lower than that of the conventional PCB.

2. Have better electrical performance and signal correctness.

3. Increase line density.

4. Better reliability: improved thermal properties/ RF interference / electromagnetic interference / electrostatic discharge (RFI / EMI / ESD).

No matter which product you are working on, you may already know how HDI PCB can make your electronic products better above information. CTT is a pcb board manufactuer with 18 years' experience. Welcome to contact me if you have any questions or need!