Company News

Aug. 22, 2024

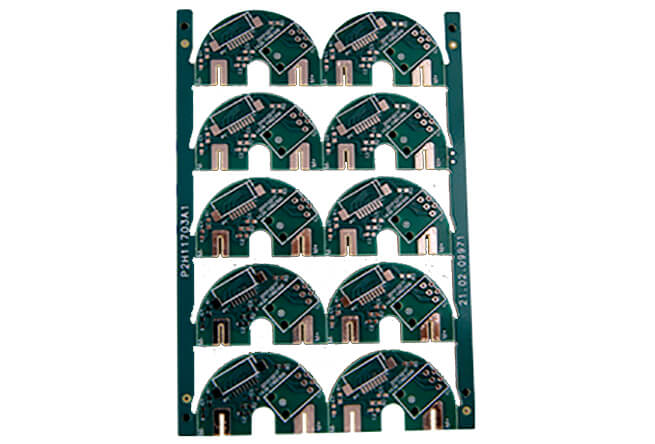

Custom PCB Exporter shares that PCB distortion is a common problem in SMT mass production. The main reasons include: PCB itself raw materials selection is improper, especially paper-based PCB, its processing temperature is too high, will make PCB distortion; Unreasonable PCB design and uneven distribution of components will result in excessive thermal stress of PCB. Connectors and sockets with larger shapes will also affect expansion and contraction of PCB and even permanent distortion. Double-sided PCB, if one side of the copper foil retained too much (such as ground wire), and the other side of the copper foil is too little, will cause uneven shrinkage on both sides and deformation; Excessive temperature during reflow welding will also cause PCB distortion.

The solution is to choose PCB with better quality or increase the thickness of PCB to obtain the best aspect ratio when the price and space allow. PCB should be designed reasonably, the area of double-sided copper foil should be balanced, and PCB should be preheated before pasting; Adjust fixture or clamping distance to ensure PCB thermal expansion space; Welding process temperature as low as possible; When slight distortion has occurred, it can be placed in the positioning fixture and reset by heating to release the stress.

Welcome to purchase our Custom PCB!