Company News

Aug. 21, 2024

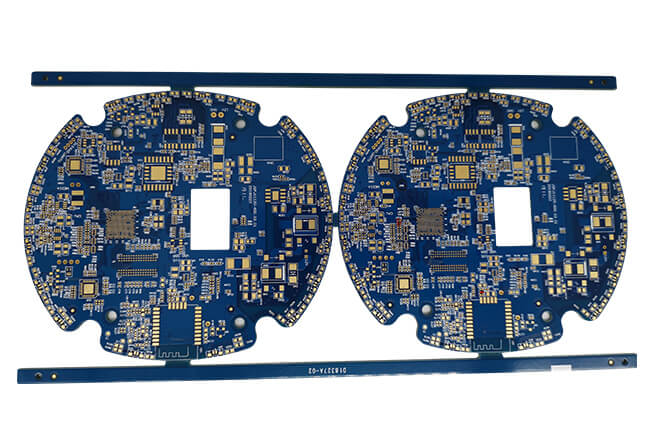

PCB circuit board by China PCB fabrication manufacturer is widely used in China, and pollutants will be generated in the manufacturing process of printed circuit board, including dust and debris in the manufacturing process such as residual flux and adhesive. If the PCB board is not able to effectively clean the surface, resistance and leakage will lead to PCB board failure, which will affect the service life of the product. Therefore, cleaning PCB is an important step in the manufacturing process.

Semi-water cleaning mainly USES organic solvents and deionized water, plus a certain amount of active agents, additives composed of cleaning agents. This cleaning between solvent cleaning and water cleaning. These cleaners are organic solvents, flammable solvents, high flash point, low toxicity, safe to use, but must be washed with water and then dried.

Water purification technology is the future development direction of clean technology, it is necessary to establish pure water source and discharge water treatment workshop. A series of water-based cleaning agents are formed by adding surfactants, auxiliaries, corrosion inhibitors and chelating agents with water as the cleaning medium. Water solvents and nonpolar contaminants can be removed.

Used in the welding process without cleaning flux or solder paste, directly into the next process of cleaning after welding, no longer free cleaning technology is currently the most commonly used alternative technology, especially mobile communication products are basically disposable method to replace ODS. Solvent cleaning is mainly used for solvent dissolution to remove pollutants. Solvent cleaning because of its rapid volatilization, strong solubility and other characteristics, the requirements of simple equipment.

The above four cleaning technologies shared by electric circuit board assembly manufacturer can achieve a certain cleaning effect, but how to clean PCB quickly and effectively? The application of ultrasonic cleaning machine can be solved. It USES the effect of uhf converting into kinetic energy in liquid medium to produce cavitation effect, forming countless tiny bubbles, and then hits the surface of the object, making the surface dirt off, so as to achieve the effect of cleaning. Because it is through the liquid, as long as the liquid can touch the surface of the surface can be cleaned in place, leaving no dead space.

It can work on every surface of multiple objects simultaneously. This is very efficient and fast and can be cleaned for about 15 minutes. An advantage of using ultrasonic cleaning is that it can effectively reduce, improve the ability of pads and components, and reduce electromagnetic interference.