Company News

Aug. 22, 2024

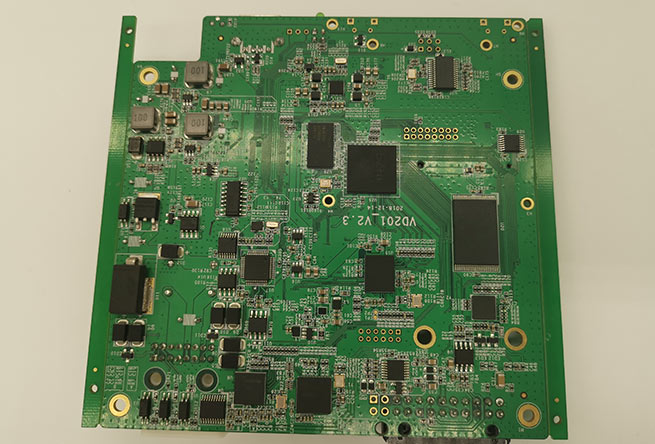

How does Shengxu ensure the quality of PCBA processing?

In the PCBA workshop, it has become a habit to focus on quality. Then how to ensure the pcba processing quality? Why can assure the qualified rate of the product reach 98% above? Below the PCBA Manufacturer Shengxu electronic technicians to introduce how to ensure the PCBA processing quality?

1. Ensure the purchase and acceptance of raw materials.

Imported high quality raw materials: lead-free solder paste is made of Japanese brand KGKI (s3x481m406-3), and high purity lead-free solder rod is selected.

Abundant supplier resources and cheaper bulk purchase price. With long-term cooperation with suppliers, it can realize mass purchase of products and reduce costs.

2. Ensure effective process production quality and implementation process.

Excellent engineering skills: senior front-end engineer and test engineer, assisting customer analysis; PCB design and proofing, according to the test plan can effectively analyze the cause and effect of all products, qualified orders.

3. Focus on the quality inspection of products.

With advanced production equipment and testing equipment, BGA stickers fan 0. 18 mh - 0. 4. The minimum packaging material packaging is 01005, MYDATA Sweden automatic MT production line, 3 million points of production per day and the top quality control and testing equipment.

Strictly control the quality control level of the high quality pcb circuit board supplier, set QC in front of the furnace to conduct bad screening, pcba 100% visual inspection after the furnace, pcba 100% optical inspection, sampling ratio up to 60,13 temperature zone reflow soldering each product independent set temperature.

4. Do a good job in quality prevention and improvement.

Primary pass rate: more than or equal to 9%; delivery completion rate: 100%; Customer satisfaction, greater than or equal to 80%.

Always adhere to the high standards for the supplier team, components, production, quality inspection group and process requirements, there is no shortcut to quality. Pay attention to PCBA product quality, establish a sound product quality assurance system, with advanced technology, excellent equipment, precision testing instruments, strict scientific management, and trusted products, best-selling at home and abroad, depending on the "product is character" quality concept and good times use, by domestic and foreign users.